Perhaps reducing the blade a little, if you wish to increase detail or if you are encountering snagging. It is usually advisable to use the largest blade suggested for the material you are working on. However, the chances of breaking a fine blade on thick material increase dramatically. For example, you could in theory cut a thick 2.3mm sheet with the finest 10/0 blade It will cut, and I do this all of the time with very intricate designs. The important thing is that at least three teeth are cutting at any time. Note this is a minimum, you can also cut thicker material than suggested or Vice versa you can also use a smaller blade.

This will ensure you have three teeth in contact across the thickness of the metal and ensure a good cut.

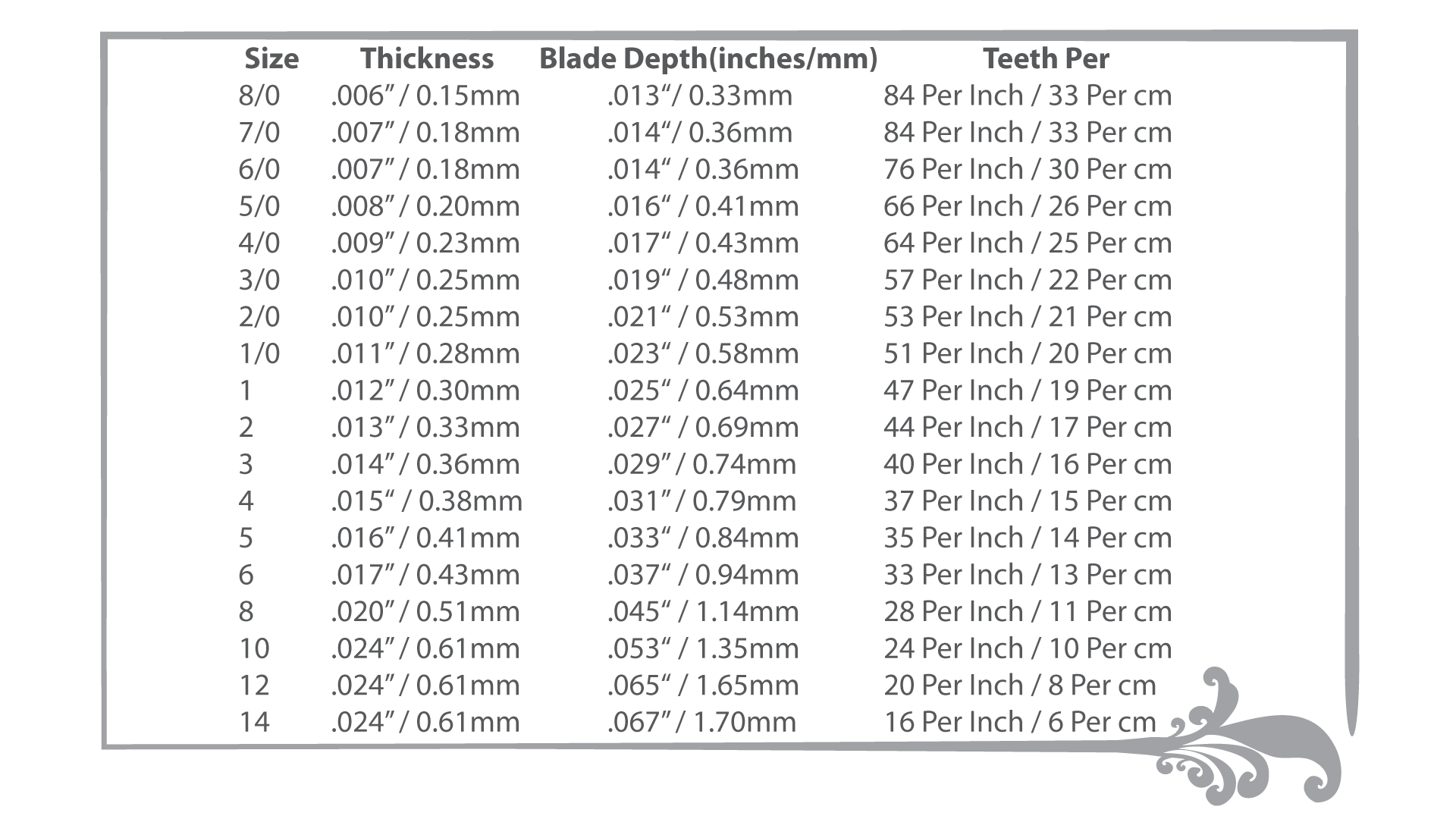

For example, if you wish to cut a 2.3mm sheet or thicker you should use a number 10 blade. This is the minimum thickness of the material recommended for each blade. This is because you may only have one or two teeth engaging with the metal, switching to a smaller blade will solve this snagging problem. Using a large blade on a thin sheet will snag and pull the sheet without cutting properly. This distance effectively determines the minimum thickness of material that the blade can effectively cut. This ensures a good cut and avoids snagging on the material. This is a vital figure, as when sawing it is important to have three teeth in contact with the metal. This is the distance across the tips of three teeth. More important than a single tooth is this figure. Provided here for information, but not a vital figure to know. The term pitch can have several meanings, but here it describes the width of a single tooth from one valley to the next. The finer blades will have more teeth but smaller. The large blades will have fewer teeth as they are larger. Teeth per CMĪs the name suggests, this is the number of teeth along 1cm of the blade. This allows for increased manoeuvrability in tight areas whilst maintaining depth and strength to the blade. Important note: Some of the new Swiss saw blades now have curved spines. Whereas a shallower blade will turn tighter and be better for very fine piercing work. A deep blade will be more difficult to turn but is often better for cutting straight lines. This determines how well the blade can maneuver around a tight corner. This is the front to back measurement, from the tip of the teeth to the back spine of the blade. However, the wider blades are much stronger and less prone to break. The larger, coarser blades are wider and so can’t cut as fine a line as the thinner blades can. This important figure indicates the cut that it can make. This is the width or thickness of the blade from side to side. For most people, a few packs of the large, medium, and fine will suffice.

10 is the largest, zero is a medium, and 10 / 0 is the finest. You can think of these as being “below” zero. Below 0, the digit increases and is followed by / 0. The numbers range from 10 which is the largest blade and reduce down through 0 zero to 10/0. This is the number that you will see on the suppliers’ websites and this is how you will buy your saw blades.

0 kommentar(er)

0 kommentar(er)